A self-monitoring system representative of wastewater discharges has been established in each factory, and serves to monitor regulated and contractual parameters such as chemical oxygen demand (COD), biochemical oxygen demand (BOD), pH, the temperature of wastewater and substances that could disturb the operation of an internal or external wastewater management facility. This self-monitoring is a tool for detecting the risk of overshooting, which helps anticipate any non-conformities and initiate corrective actions.

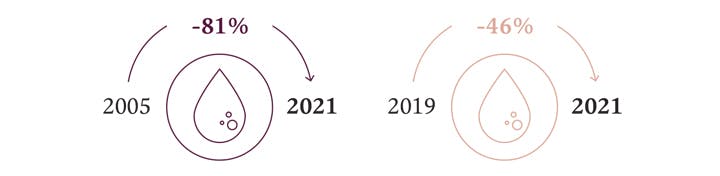

In 2021, the total chemical oxygen demand of the Group’s wastewater at the exit of the site was 0.33 grams per finished product.☑ This was down 46% in tonnes compared to 2019 (a 73% decrease compared to 2005) and by 46% in grams per finished product compared to 2019 (a decrease of 81% compared to 2005). These reductions are related to the operational start-ups of new wastewater treatment plants and the optimisation of existing treatment plants at several Group factories.

WASTEWATER QUALITY INDEX

(grams of COD per finished product)

Furthermore, as part of the L’Oréal for the Future programme, the Group has established a L’Oréal internal standard for the quality of industrial wastewater at the exit of the sites: by 2030,100% of the wastewater at the exit of factories must not exceed a chemical oxygen demand of 1,000 mg COD/l (if local regulations impose a lower threshold, the site must comply with the lower value).

At year-end 2021, 24 factories were in compliance with this internal standard ☑, representing 62% of the Group’s factories.

| Scope of industrial sites | 2020 | 2021 |

|---|---|---|

| Accidental spills (m3) | Accidental spills ( m3) 20202 |

Accidental spills ( m3) 2021 0 |

| Wastewater at the exit of the site (m3) | Wastewater at the exit of the site ( m3) 20201,039,630 |

Wastewater at the exit of the site ( m3) 2021 885,423 |

| COD at the exit the site (in tonnes) | COD at the exit the site (in tonnes) 20203,392 |

COD at the exit the site (in tonnes) 2021 2,022 ☑ |

The Group’s air emissions, excluding greenhouse gases

Industrial sites have an inventory and mapping of air emissions, which is updated once a year. The operation and maintenance of air emission collection and treatment facilities are subject to specific procedures and instructions.

| Scope of industrial sites (in tonnes) | 2020 | 2021 |

|---|---|---|

| SO2 | SO 220200.4 |

SO 22021 0.3 |

| VOC | VOC 2020143 |

VOC 2021 156 |

| Ozone depleting substances | Ozone depleting substances 20200.8 |

Ozone depleting substances 2021 1.1 ☑ |

☑ The Statutory Auditors have expressed reasonable assurance with regard to this indicator.

Noise pollution

L’Oréal’s industrial activities are not particularly noisy. The sites comply with the noise standards to which they are subject.

Internal environmental reporting is one way in which to ensure monthly readings of any non-conformity on this issue.

Provisions for environmental risks

The amount of the provisions for environmental risks is not material (see Note 13.1 of the Consolidated Financial Statements).

4.3.1.1.3. Fighting climate change on operated sites

L’Oréal has set itself a major objective of fighting climate change and preserving natural resources in the overall exercise of its activity. All efforts are being made to achieve this objective in the sites where its activities are performed and across its entire value chain, from the search for renewable ingredients and the sustainable sourcing of raw materials to the transport of products, their consumption and their end of life. L’Oréal is committed to continuously improving the impact of its products throughout their life cycle.

As part of the L'Oréal for the Future programme, L’Oréal is committed to improving the environmental footprint of all operated sites.

The Group strives to reduce greenhouse gas emissions(1), water consumption, waste generation, and to protect biodiversity. It is also committed to reducing the footprint of product transport, and no longer sending waste to landfill (without regulatory constraints).

The specific context of the Covid-19 health crisis impacted the amount of hours worked at the administrative sites and research centres, which decreased by 54% in 2021 from 2019, because of the different lockdown periods that resulted in the periodic or partial closure of some of these sites as well as an increase in telecommuting for eligible positions. The nature of the activities maintained on-sites – laboratories, pilots, etc. – which generally consume more resources than the administrative activities, increased the effects of this activity decline on certain environmental ratios (energy, water, and waste per 100 hours worked).

On the other hand, the production of the industrial sites remained stable in comparison with 2019 (decrease of 0.4%).

☑ The Statutory Auditors have expressed reasonable assurance about this indicator.

(1) In this document, the Group’s performance in terms of CO2 emissions is expressed in CO2 equivalent, i.e. CO2 eq. As per the Greenhouse Gas Protocol (GHG Protocol): Scope 1: “direct emissions from sources owned or controlled by the reporting entity”; Scope 2: “indirect emissions related to the consumption of electricity, heat or steam necessary for product processing or operating the reporting entity”; Scope 3: “other indirect emissions related to product supply chain (upstream emissions) and the use of products and services during their life cycle (downstream emissions)”.