4.3.1.1.4. Preserving water resources on operated sites

L’Oréal Group is committed to preserving water resources throughout its value chain, especially on each of the sites operated. The action plans implemented around the world are based notably on the following key principles:

- mapping the volumes of water used, particularly by the Group’s factories, using a L’Oréal internal tool that carries out a comprehensive analysis of the various uses of water on a site: the Water scan tool. Each type of use is quantified and compared with a benchmark value in order to identify potential reductions;

- the installation of reduction equipment and processes, particularly during the cleaning phase of production equipment and factory filling and packing lines, following the OPTICIP (OPTImisation Cleaning In Place) approach developed by L’Oréal; and

- the reuse of untreated industrial water for a new purpose and recycling of the water used, after a specific additional treatment step.

By the end of 2021, 17 Group factories had such recycling facilities allowing them to reuse process water.

As part of the L’Oréal for the Future programme, the Group set a new target for 2030: 100% of the water used in our industrial processes will be recycled and reused in a loop, i.e. 100% of factories will be Waterloop factories.

At the end of 2021, 6 factories ☑ were awarded the status of Waterloop Factory, i.e. 15% of the Group’s factories.

The “Waterloop Factory” concept

The “Waterloop Factory” concept consists of using city mains water only for human consumption and for the production of the high-quality water used as raw material for product processing; all the water required by the utilities(cleaning equipment, steam production, etc.) is derived from water that is reused or recycled in a loop on the site.It involves the implementation of a two-step system:

- the optimisation of industrial processes in order to minimise water consumption, which leads to a reduction of water withdrawals; and

- the installation of a water recycling system: industrial wastewater, after pre-treatment in the on-site treatment plant, are reprocessed using various technologies(ultrafiltration, reverse osmosis, nanofiltration, etc.) in order to extract very high-quality water. This is then used in a loop to clean production tools and services as a replacement for municipal mains water. As such, water requirements for utilities are fully covered.

The Waterloop Factory concept was adopted for the first time in 2017 by the Burgos factory in Spain. In 2021, this concept was also extended to the factories in Settimo in Italy, Vorsino in Russia, Libramont in Belgium, Mexico City in Mexico and Yichang in China. It will gradually be deployed to all Group factories.

WATER WITHDRAWAL AT INDUSTRIAL SITES

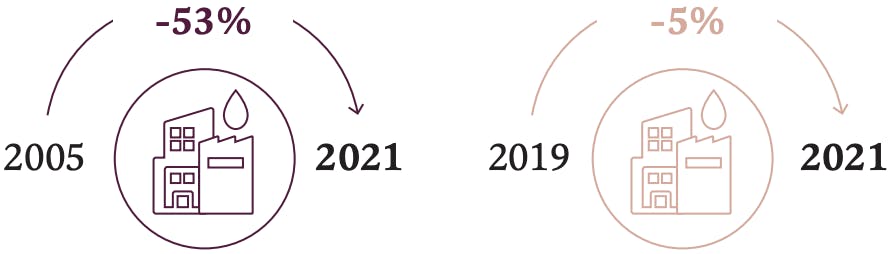

As part of the L’Oréal for the Future programme, the Group has set itself a new target for 2030: to reduce the water withdrawal of factories and distribution centres by 30% per 100 hours worked by 30%, compared to 2019.

The total volume of water withdrawal of the industrial sites at the industrial sites was 2,057 thousands m3 for 2021 ☑, decreased by 5% compared to 2019, while the production of finished products decreased by 0.4% over the same period.

Water withdrawal was 0.34 litres per finished product in 2021☑,representing a decrease of 5% from 2019 (and a decrease of 8% from 2020).

(in litres per finished product)

☑The Statutory Auditors have expressed reasonable assurance about this indicator.