Reducing waste generation at source

Waste reduction requires the involvement of a large number of players. It is an environmental performance indicator, first for its industrial sites, administrative sites, and research centres, but also across the entire value chain of the Group:

- for the packaging teams, who are mobilised through an eco-design approach to filling and packing components and transportation packaging (reduction of weight, optimisation, reuse, etc.) aimed at reducing waste and improving their recyclability;

- for the purchasing teams, privileged contacts with suppliers, with the aim of optimising filling and packing used for the transportation of raw materials and packaging components received in the Group’s factories, a major source of waste. The development of the wall-to-wall approach (production of filling and packing components close to the Group’s production facilities) is a particularly effective means of reducing waste related to the supply of components at the source;

- for the industrial teams involved in a process of continuous improvement of manufacturing and filling and packing processes in order to reduce losses during production;

- for the Supply Chain teams who are working to reduce obsolete inventories, which is essential for the reduction of waste related to the Group’s business activities. In each zone, programmes combine industrial agility and improved sales forecasts with the aim of reducing obsolete products, and ensuring better flows via the establishment of outlets, family sales, sales to staff and donations to not-for-profit organisations.

Furthermore, the Group has initiated a campaign against wasting food. In 2021, an average of 3,297 meals were served daily in the Paris region. Company restaurants, both those directly managed and those operating under agreements, donated the surplus food from these meals to associations such as Restos du cœur or Le Chainon Manquant, bringing the number of meals donated in 2021 to 3,973.

L’Oréal adopts best practices in its directly managed restaurants. An awareness programme for employees, the recovery of 100% of food waste via the Bio-Waste system, very strict monitoring of use-by dates and inventories, real-time and on-demand cooking methods, and attention to the quantities served have been implemented in the restaurants.

A number of initiatives are also taken to develop responsible, fair and sustainable food in the Group’s restaurants and cafeterias. For example, the development of a fair trade coffee supply, the proportion of local products from organic farming, or the priority given to seasonal fruits and vegetables in menu preparation are applied.

The campuses in the Paris region also initiated actions to reduce plastic use (elimination of plastic bottles and glasses for services in rooms and the elimination of plastic glasses in cafeterias) and to recycle cooking oil into biofuel.

For example, the Aulnay-sous-Bois campus developed a special partnership with the French Restaurants du Cœur charity based on a food donation agreement for more than 3,455 meals in 2021 and solidarity sales. It also made the choice for supplies exclusively based on free-range eggs. Finally, for all its efforts, it earned the “Mon restau responsable” label established by the Fondation Nicolas Hulot for a quality food service that respects the environment. This label is granted for four areas: the well-being of guests, sustainable meals, eco-friendly practices, and a social and local commitment.

GENERATION OF TRANSPORTABLE WASTE FROM INDUSTRIAL SITES

(in grams per finished product, excluding sludge and returnable packaging in rotation, including returnable packaging at source)

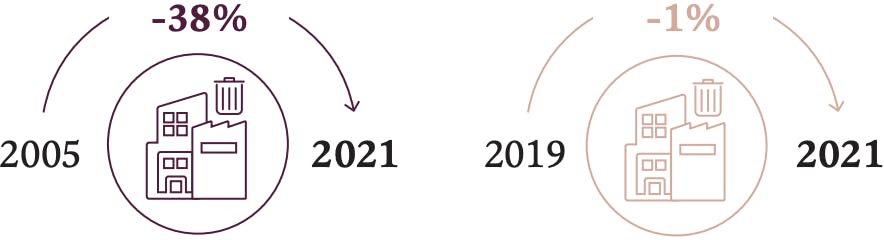

Waste generation at the industrial sites was 80,363 tonnes for2021 ☑, which is a decrease in absolute value of 1% from 2019 (this waste does not include the sludge generated by the plants treating the wastewater from Group sites), while the production of finished products was down 0.4% over the same period.

In 2021, waste generation for the industrial sites was 13.1 grams per finished product☑, representing a 1% decrease from 2019 (an increase of 3% from 2020).

GENERATION OF TRANSPORTABLE WASTE FROM ADMINISTRATIVE SITES AND RESEARCH CENTRES

(kilograms per 100 hours worked, excluding sludge and returnable packaging in rotation, including returnable packaging at source)

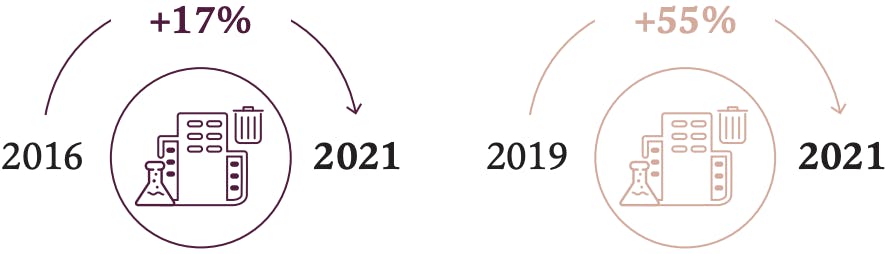

Waste generation at the administrative sites and research centres was 4,466 tonnes in 2021, a decrease in absolute value of 29% compared to 2019 (this waste does not include the sludge generated by the wastewater treatment plants at the Group’s sites).

In 2021, waste generation from these sites was 13.3 kilograms per 100 hours worked, an increase of 55% from 2019 (22% increase from 2020).

☑The Statutory Auditors have expressed reasonable assurance about this indicator.