Manufacturing performance that relies on a global system of operational excellence

L’Oréal has 39 plants around the world incorporating the latest advances in technology, automation and digitalisation, close to the needs of consumers in L’Oréal’s key growth markets. This network of plants adapts constantly to incorporate acquisitions and embrace external innovations. It is supported by a network of subcontracting partners to deal with cyclical peaks in demand for specific technologies (make-up pencils, soaps, etc.).

The Group’s manufacturing organisation is also based on specialisation by technology (haircare, skincare, makeup, perfumes, etc.) to maximise best practices, increase agility, improve productivity, adapt more easily to the specific needs of local clients and consumers, and to optimise investments.

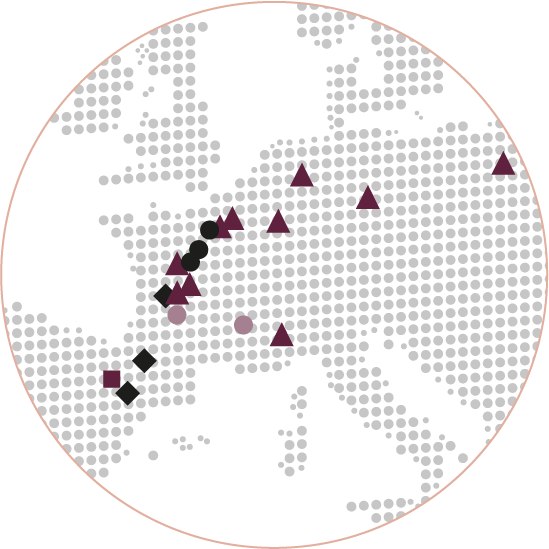

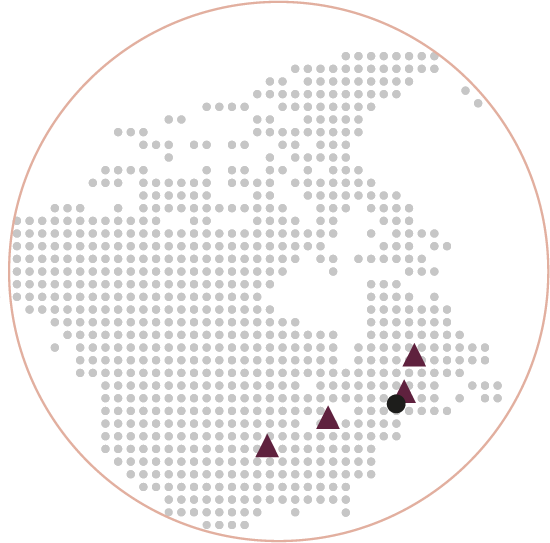

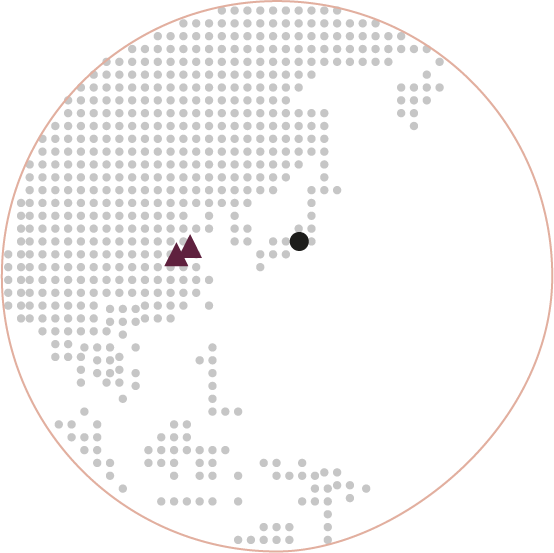

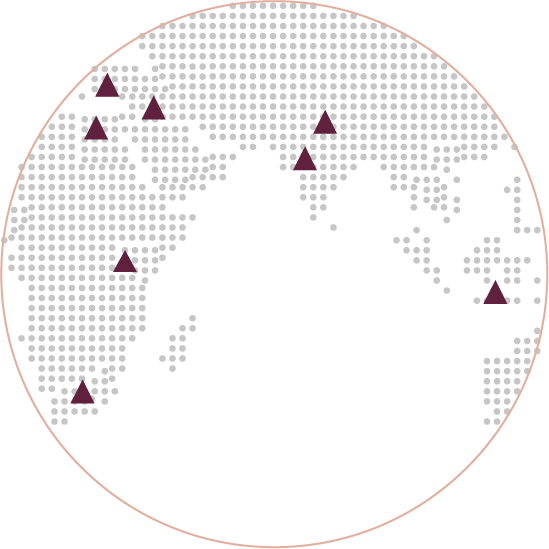

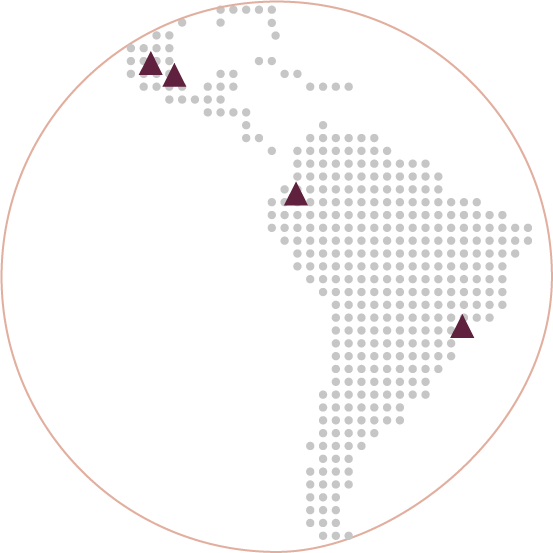

MANUFACTURING FOOTPRINT BY GEOGRAPHIC ZONE

EUROPE

NORTH AMERICA

NORTH ASIA

SAPMENA - SSA

LATIN AMERICA

Operational excellence

L’Oréal’s industrial sites are equipped with high-tech innovations, including robotic technologies, automation and cobotics (collaborative robots), for the flexibility required to meet the demands of the market and consumer needs: from high-productivity plants for large-scale production to agile plants producing limited editions.

The Group is continuing to roll out its Operational Excellence System in all its plants to meet the challenges of a constantly changing world and go even further in adapting its manufacturing equipment to the needs of consumers. This approach relies on the involvement of all Operations employees in technical and technological areas related to safety, quality, service levels, productivity, ergonomics and environmental impact, while promoting commitment.