At year-end 2021, there were six Waterloop Factory plants (Burgos in Spain, Settimo in Italy, Vorsino in Russia, Libramont in Belgium, Mexico City in Mexico and Yichang in China): all the water required by the utilities (equipment cleaning, steam production, etc.) comes from reused water or water recycled in a closed loop on the site (see section 4.3.1.1.4., Preserving water resources on operated sites, in this document).

L’Oréal’s commitment for over 25 years to environmental leadership was recognised in 2016, 2017, 2018, 2019, 2020 and 2021, with the best possible rating by the CDP(1): a triple "A". L’Oréal is thus the only company in the world, out of more than 12,000 companies assessed, to receive a triple “A” ranking for the sixth consecutive year, for its commitment and results in each of the key areas for environmental protection: the fight against climate change, sustainable water management and the fight against deforestation.

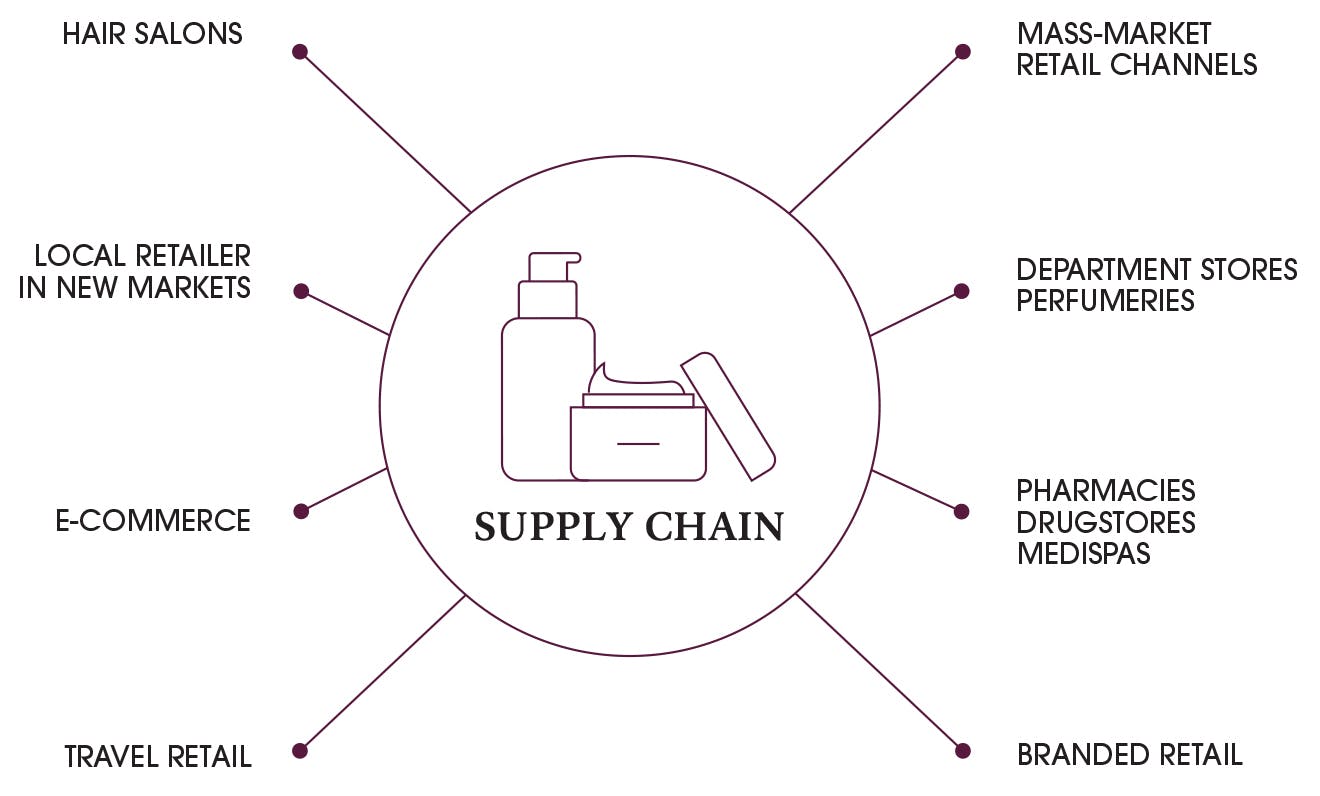

Rapidly changing omni-channel logistics strategy

L’Oréal Group’s supply chain organises and optimises all product delivery flows to all our customers as well as direct deliveries to e-commerce consumers. It is responsible for making sure that the products are delivered under optimum conditions, at the right time and at the best cost. L'Oréal distributes more than 6 billion products accross all channels. The supply chain and its distribution centres were particularly strategic and responsive in 2021 in order to provide deliveries to consumers and thus support L’Oréal’s growth, despite a challenging global context in the supply of raw materials and transport.

L’Oréal is unique in the cosmetics market in that it serves a global market through a diverse range of distribution channels (see below) with a portfolio of many different beauty and cosmetic product categories. L’Oréal continuously optimises all information flows and physical flows from suppliers to customers.

This diagram shows the supply chain:

MASS-MARKET RETAIL CHANNELS

DEPARTMENT STORES PERFUMERIES

PHARMACIES DRUGSTORES MEDISPAS

BRANDED RETAIL

TRAVEL RETAIL

E-COMMERCE

LOCAL RETAILER IN NEW MARKETS

HAIR SALONS

The goal is to increase agility to handle market variations on all distribution channels and to adapt to market expectations in real time. L’Oréal has therefore implemented a planning strategy for the manufacturing, sales and distribution process (S&OP, Sales and Operations Planning) in order to deliver an optimum service to the Group’s customers. Digitalisation of the supply chain and data management are critical challenges, and represent a real opportunity, especially in the retail sector and in stores managed directly by L’Oréal. It can provide a comprehensive view of business in a store, as well as improve understanding of the consumer purchase journey.

The supply chain network composed of 148 distribution centres is a strategic lever to ensure agile coverage of market challenges and expand our service offer. To create a more responsive supply chain, L’Oréal is investing in its plants to gradually transform them into Fulfilment Centres for more services: powered by automation and data, they will manage a range of services to consumers such as personalisation, box preparation, tailor-made delivery, and so on. They will facilitate stock interoperability for omnichannel management and allow enhanced product traceability for greater transparency to consumers. In France, the Mitry-Mory plant in the Paris region was transformed to meet the changing demands of hairdressers with an increasing number of small and split orders, based on the direct to consumer model.

Sustainable development is also central to the supply chain strategy. In order to reduce its environmental footprint, L’Oréal is co-creating with carriers low-carbon multimodal solutions adapted to the specific features of each geographic zone (green delivery, reduced air freight, hydrogen engines, etc.). To improve the energy efficiency of its centres, L’Oréal is increasing the use of 100% renewable energies everywhere in the world and is also targeting the elimination of the use of single use plastic in its centres.

By the end of 2022, the aim is to eliminate single-use plastic in materials used to fill packaging voids or in adhesive tapes in all distribution centres worldwide. By the end of 2021, 100% of the Group’s distribution centres in Latin America, Europe and SAPMENA-SSA had already achieved this goal.

(1) The CDP is an independent NGO which offers a global system for the measurement and publication of environmental information and which assesses the strategy, close involvement and results obtained by companies in the fight against climate change, sustainable water management and forest protection.